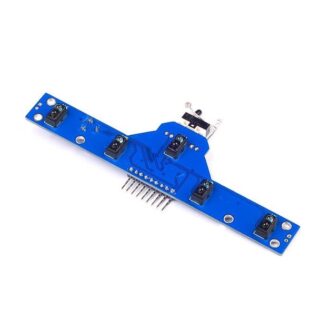

The Flex Sensor 2.2″ is a thin, flexible resistor that changes its resistance when bent. It is commonly used in robotics, wearables, and interactive electronics projects.

When the sensor is straight, it has a lower resistance, and as it bends, the resistance increases. This allows microcontrollers such as Arduino, ESP32, and Raspberry Pi to measure bending or angle using a simple analog input.

Key Features

Length: 2.2 inches

Resistance varies with bending angle

Thin, lightweight, and flexible

Easy to interface with microcontrollers

Durable for repeated bending

Applications

Robotics and motion detection

Wearable electronics and smart gloves

Gesture-based control systems

Educational and prototyping projects

Compatibility

Arduino boards

ESP8266 / ESP32

Raspberry Pi (with ADC)

Other microcontrollers with analog input

This 2.2″ flex sensor is ideal for students, hobbyists, and engineers looking for a reliable flex sensor in Kenya for prototyping and learning.

You must be logged in to post a review.

Related products

-

DS18B20 Temperature Probe Sensor

KSh 200.00 – KSh 500.00Price range: KSh 200.00 through KSh 500.00Select options This product has multiple variants. The options may be chosen on the product pageDS18B20 Waterproof Temperature Probe Sensor. Description: Purpose: This sensor is used to measure temperature in …

-

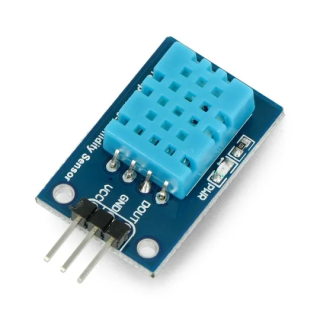

DHT11 temperature & humidity sensor

KSh 450.00Add to cartThe DHT11 sensor is widely utilized in numerous STEM projects for detecting humidity and temperature. It offers several advantages, including its low cost, ease of use, and digital output. These features make it a popular choice among developers and hobbyists alike

Products

-

Electrical hand Gloves

KSh 1,300.00

Electrical hand Gloves

KSh 1,300.00

-

1.5mm² Flexible 3-Core Cable Per Meter

KSh 80.00

1.5mm² Flexible 3-Core Cable Per Meter

KSh 80.00

-

16V 47uF capacitor

KSh 10.00

16V 47uF capacitor

KSh 10.00

-

Soldering Wire Spool

KSh 1,300.00

Soldering Wire Spool

KSh 1,300.00

-

Bulb 7W

KSh 150.00

Bulb 7W

KSh 150.00

![AD8232 ECG Measurement Pulse Heart Sensor AD8232[KIT]](https://bluepacknova.com/wp-content/uploads/2024/07/51SJY1azEEL._AC_UF10001000_QL80_-1-320x320.jpg)

Reviews

There are no reviews yet.