Small Reduction Stepper Motor – 5VDC 32-Step 1/16 Gearing

KSh 350.00

Explore the Precision of Small Reduction Stepper Motors – Ideal for Precise Control in Robotics, 3D Printing, and Automation. Learn how these compact motors with high-precision reduction gearboxes can elevate your projects. Discover reliability and accuracy with Small Reduction Stepper Motors.

In stock

Small Reduction Stepper Motor

This particular stepper motor is an excellent choice, especially for beginners and smaller projects. It provides an ideal opportunity to experiment with stepper motors due to its user-friendly features. It’s categorized as a unipolar motor, which means it’s easy to work with, and it even includes a built-in mounting plate with two holes for straightforward installation.

In terms of its stepping capabilities, this motor takes 32 steps per revolution, which corresponds to an angle of 11.25 degrees for each step. It incorporates a 1/16 reduction gear set, which can be approximated as 1/16 for practical purposes. When you combine these features, the motor effectively offers a total of 513 steps per revolution (32 steps * 16.032). This is quite useful for precise control in various applications. Furthermore, the motor has a flattened shaft, making it simple to attach components securely using a set-screw.

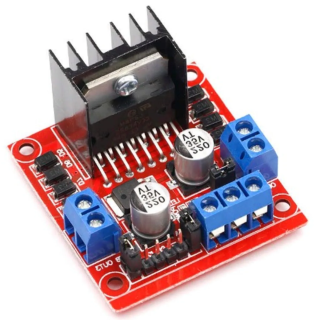

In summary, this stepper motor serves as an ideal starting point for beginners in the world of stepper motors. It pairs seamlessly with the Motor Shield for Arduino, enhancing its usability and versatility across a wide range of projects.

Specifications of the stepper motor:

- Type: Unipolar stepper motor with a 0.1-inch spaced 5-pin cable connector

- Stepping: 8 steps per revolution

- Reduction Gear: 1/64 geared down reduction

- Suggested Operating Voltage: 5V DC

- Weight: 37 grams

- Dimensions: 28mm in diameter, 20mm in height (excluding the 9mm shaft with a 5mm diameter)

- Cable Length: 9 inches (23 cm)

- Holding Torque: 150 gram-forcecm (equivalent to 15 Nmm or 2 oz-force*in)

- Shaft: 5mm diameter with a flattened shape for secure attachment of components.

A “Small Reduction Stepper Motor” is a specific type of stepper motor with a built-in reduction gear mechanism designed to reduce the rotational speed and increase torque output. This type of stepper motor is often used in applications where precise control of rotational motion, as well as increased torque, is required. Here are some key features and characteristics of a Small Reduction Stepper Motor:

- Stepper Motor Type: These are typically of the bipolar or unipolar type, depending on the specific model. These motors are known for their ability to move in precise, discrete steps, making them suitable for applications that require accurate positioning.

- Reduction Gear: The defining feature is the inclusion of a reduction gear mechanism. This gear mechanism reduces the speed of the motor’s output shaft while increasing its torque output. This is especially useful in applications where high torque at low speeds is necessary.

- Applications: Are commonly used in various applications, such as robotics, CNC machines, 3D printers, camera systems, and any other application where precise and controlled rotational motion is required. The reduction gear makes them well-suited for applications like moving heavy loads or controlling the position of mechanical components.

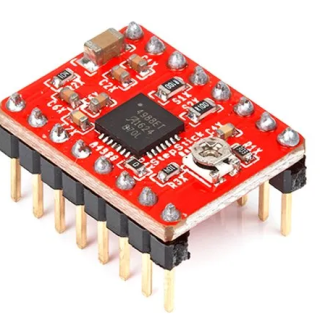

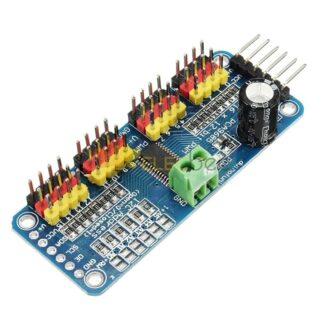

- Control: Like other stepper motors, Small Reduction Motors are controlled using pulses or step signals. Each step corresponds to a specific angular movement, making them easy to control and position accurately. The degree of reduction provided by the gear mechanism affects the motor’s overall step resolution and torque output.

- Size and Form Factor: These motors come in various sizes and form factors to accommodate different application requirements. The specific size and dimensions of the motor may vary depending on the manufacturer and model.

- Voltage and Power: The operating voltage and power requirements of Small Reduction Stepper Motors can vary. It’s essential to match the motor’s voltage and power specifications to the requirements of the application and the control electronics used.

- Mounting: These motors often come with mounting options, such as threaded holes or brackets, to facilitate easy installation in various configurations.

- Direction Control: These motors can rotate in both clockwise and counterclockwise directions, making them versatile for different applications.

- Maintenance: Proper maintenance, including lubrication of the reduction gear, is essential to ensure the motor’s longevity and reliable performance.

In summary, a Small Reduction Stepper Motor is a specialized type of stepper motor equipped with a built-in reduction gear mechanism. It is commonly used in applications where precise control of rotational motion and increased torque are necessary, making it a valuable component in various industrial and automation settings.

learn more about mechatronics from Eng Glenn gatiba

You must be logged in to post a review.

Reviews

There are no reviews yet.